If you’ve been paying attention you’ve seen that more and more streetwear brands are bringing back the Puff Ink prints. This type of ink is a plastisol based ink that has been modified with the addition of a heat reactive foaming agent that makes the ink expand tp give you that ‘Puffy’ look.

How Does It Work?

Puff ink adds a 3 dimensional aspect to screen printing on garments. With this type of ink, you will follow the same screen printing steps as printing with standard water-based inks.

You can use puff ink across the entire artwork, or you can choose specific elements or colors of the design to give it the desired effect to bring more attention or 'pop' to a particular part of the artwork.

One of the downsides to printing with puff ink is that it’s hard to match the exact Pantone ink colors as opposed to using regular water-based ink. This is because the puff ink additive changes different colors in different ways. However, usually, lighter Pantone colors are easier to match than darker colors.

Keep It Simple

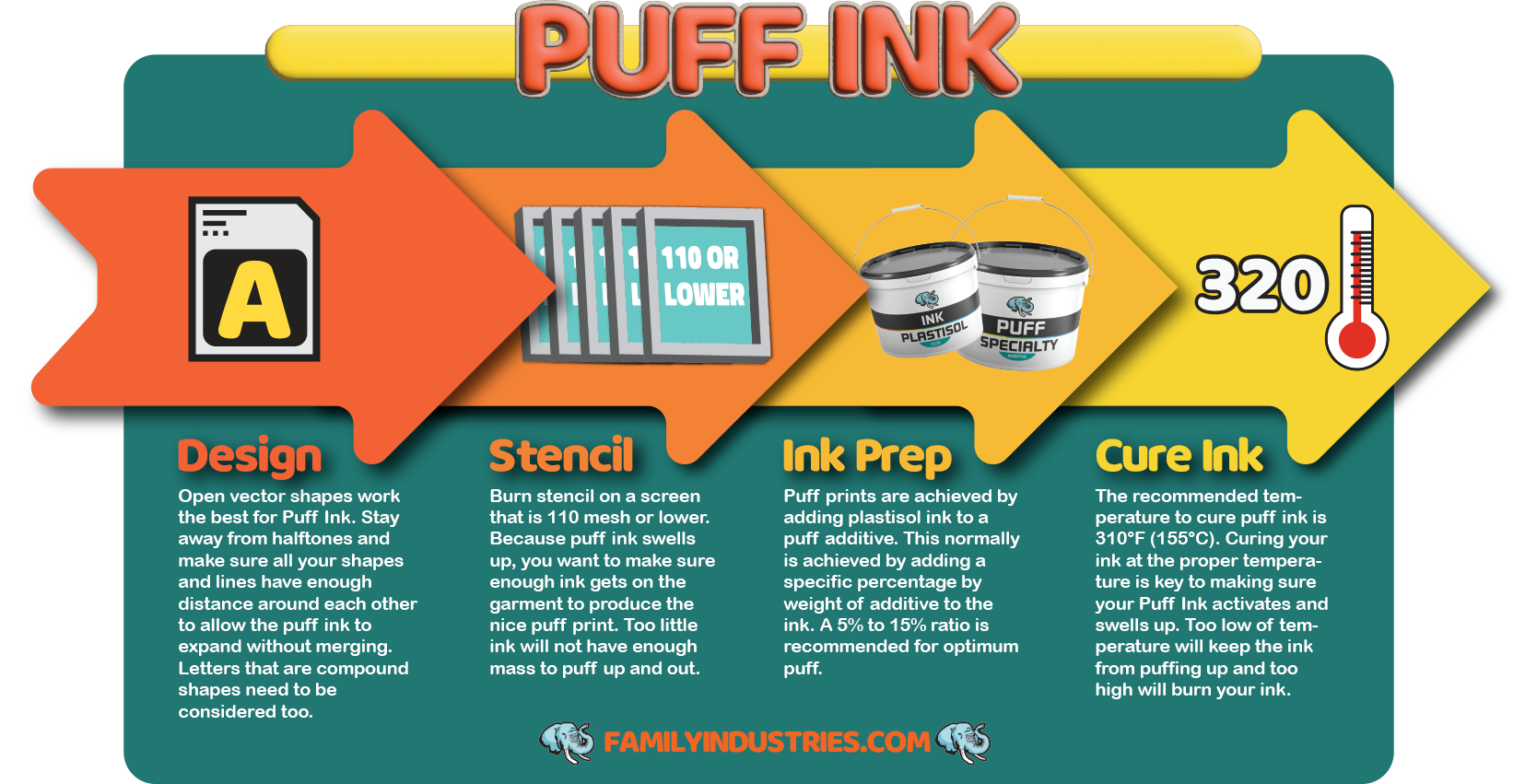

There are no fundamental limitations when using puff ink for t shirt printing, apart from when your design has small details that are less than 1 - 2mm wide. For the best puff print, you will want your design to have thick lines and minimal small details. When creating a design featuring text, choosing the right font is key. The thicker the lines the more your design will stand out.

Check out How To Add Puff Additive To Plastisol Ink

How It’s Made

You should use plastisol inks of any color and add a puff additive such as “Rutland NPT puff’ which recommends a 5% to 15% ratio for an optimum puff. The amount of additive dictates how much the ink will rise. With puff ink, it’s important to measure how much additive and paint to mix by weight.

When it comes to your screen, the lower the mesh count, the more open the holes are, which translates to more ink deposit and results in a more “puffy” print.

Once you’ve added the ink to your garment in the chosen design, as the ink goes through the dryer and the heat rises, so does your ink. Like a loaf of bread!

Aftercare

To preserve a puff print or any other specialty prints, it is recommended that you wash it inside out with cold water. Do not use a tumble-dryer, hang dry if possible and do not iron over the print.

Check out Puff Ink – The definitive designers guide for apparel creation

Pro’s and Con’s List

Pros of Puff Screen Printing

Fast printing technique for printing in large volumes

Can be printed in conjunction with a wide selection of other inks and effects

Can produce designs with multiple colors

High-durability, will not crumble and flake off

Professional finish and usually less expensive (consult with your printer)

Can print on most types of fabrics

Cons of Puff Screen Printing

Initial setup fee makes it unsuitable for small quantity orders

Not good for use in fine detailed artwork

Can not be used for image (raster based) prints

Can not be printed alongside, foil, flock or high density print effects

Are you looking to printing

your design with Puff Ink?

Get the inside scoop from Lee Stuart printing with Puff Ink for the first time!

Brand Spotlight

Japangeles is a Los Angeles based streetwear brand located in the heart of Little Tokyo. Japangeles has done collaborations with other major brands such as Kirin, Hello Kitty, Champion, and Lexus. Their simplistic yet eye-catching approach to design and word play has caught the attention of many people looking for high-quality garments and minimalistic aesthetics in Los Angeles. Their newest design features a puff ink print, demonstrating the current popularity of this type of specialty print method.

Author: Irene Floridia - Content Creator

Follow us on Instagram and Facebook!

For FAQ, check out our site!

For any inquiries, send us a message!

OR

send us an e-mail at quotes@familyindustriesla.com