The art of screen printing has been around since the late 900s, and as with any industry that gains popularity over time, innovation is no stranger to the world of printing. With so many print styles to choose from, it isn’t always easy to match the right style with the right project. No one understands how difficult this decision can be more than us at Family Industries. With over a decade of experience, we’ve seen it all.

The two most popular forms of apparel and art printing are Screen Printing and Digital Printing. For some, the differences in the finished product can often be indistinguishable. However, the contrast between these two styles extend far beyond the print itself. That’s why we thought we’d take a stab at helping you figure out which print style works best for your next order.

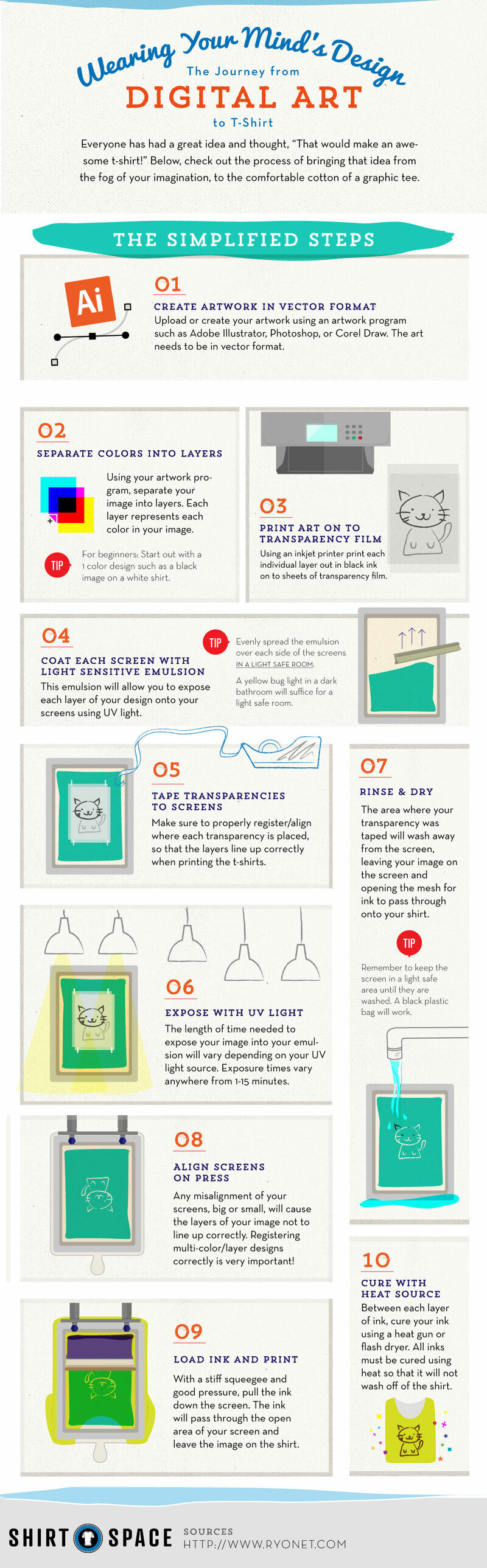

What is Screen Printing?

The screen printing process involves a silkscreen with your image. The inks are applied by color and by layer unto the printing surface one at a time. Screen printing is very versatile, and the technique can be used to print on many different types of material such as textiles, plastic, and latex. Check how does screen printing work?.

Screen printing is the most widely known and used method, as it has been around for a very long time. Technology has made some advancements in this method to speed up the process but its main functions have not changed, it is still ink being pushed through a stenciled screen.

Screen Printing Pros

Color vibrancy - Screen printing uses Plastisol inks and water-based inks, which are the most vibrant colors available, while digital printing is limited by the CMYK color gamut. It is also easier for screen printers to match the exact color, especially when using the Pantone Matching System.

Durability - Digital prints can deteriorate as you wash your clothes, especially if you are washing with hot water. While screen printing does not have this problem, if done correctly, your print will retain its color and vibrancy for a long time.

Versatility - With screen printing, you have the ability to print on many different textiles, garment styles, print locations, and placements. While digital printing is limited to the type of textiles and placement.

Special effects - From raised print to texture, shine, sparkles, or glows, there’s a special ink or additive that can do it and it can only be done with screen printing. Digital printing now has some specialty inks but they are not widely available or as easy to accomplish.

Check out the different types of special effects possible with screen printing:

Water-based

Absorbs into the fabric for a very lightweight and soft print.Discharge

Chemically removes the dye from the pigment of the fabric.Puff

This additive expands while being cured, for a soft, raised feel.Fluorescent

Very bright neon colors, also known as “day glow”.Metallic

Popular ink for a shiny look. Typically in gold, silver, or copper.Glitter

Contains glitter for a sparkly look, often combined with a clear gel.Glow-in-the-dark

Almost clear, light-activated ink that glows in the dark.Suede

Similar to puff, but creates a soft and fuzzy texture to the surface.High-density

Creates raised layers of rubber-like ink for a 3-dimensional print.Soft Hand

Additive for reducing the thickness of ink for a softer feel.Clear Gel

A thick glossy coating that can be used in combination with others.Shimmer

Creates a unique reflective, iridescent shine.Crackle

Splits and cracks during curing for a naturally distressed look.Plasticharge

Combines the best of Plastisol and discharge.

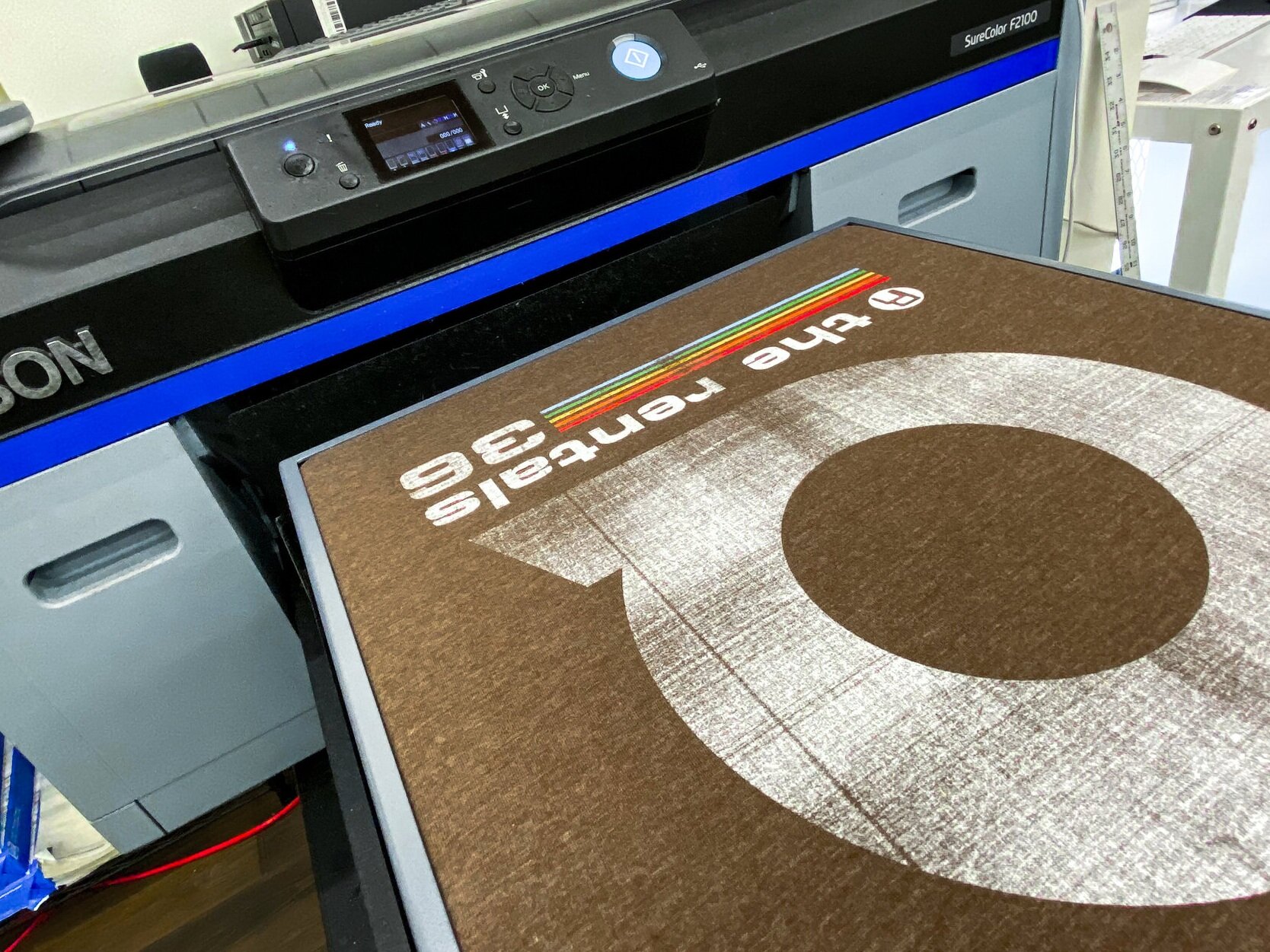

What is Digital Printing?

This process is much newer and involves specialized inkjet printers developed to print textile inks. The image on the screen is converted into a format that can then be printed unto the surface required. Digital printing is typically used when the print requires more details and this method is very versatile as it can be used on any type of surface. Check out how Digital Printing works.

In the Print Industry, “digital printing” is more of a term than an actual method of printing. In the world of Screen Printing, “digital printing” is typically referred to as “Direct to Garment”. While Screen Printing has been around for centuries, Direct to Garment printing has only been around for about 15 years. As society has grown more impatient over time, people are always looking for instant gratification. The majority of online on-demand printing companies use this as a primary method because of the speed and accuracy with minimal set-up.

Digital Printing Pros

Details - Designs with a lot of detail or photographs usually require a more precise and clear print. These types of designs are better candidates for digital printing.

Color Blending - Photographs or intricate designs will require color blends that may be more difficult to achieve with screen printing, for this reason, digital prints would be a better option.

Consistency - Your print is most likely to be consistent all throughout when printed digitally as the file is set-up by a computer and the consistency of the ink is distributed at the same rate for each piece.

Quantity - Digital prints require less of a set-up, therefore, allowing for a much-limited amount of prints to be done, while most printing services have a minimum quantity for screen printing.

So, Which Print Method is The Best?

The best method depends on what you intend on printing and the surface. The look is different as the digital printing allows for a more precise, crisp, and detailed print while screen printing provides a more authentic, softer, and retro look. Because both methods are good and serve different purposes, here are a few things to consider before making your decision.

Quantity: Digital printing allows for a smaller quantity to be printed while screen printing will usually require a minimum.

Apparel: Screen printing has more versatility when choosing your fabric. For digital printing, it is advised to print on 100% cotton or other select cotton blends and only certain colors.

Design: Photographs or hyper-detailed images with a lot of colors are usually better printed digitally. However, if you have a large number of shirts you would like to print, screen printing may still be an option but it may cost you a little bit more or may require some adapting to make the design work best.

For some people it may come down to cost, so we will take you through what will dictate your cost based on several factors for both methods.

Apparel: The type of apparel can range from value to premium options and depends on the style and brand.

Print Locations: There is the option for 1 or 2 locations, which would be the front and/or the back (for a t-shirt or sweatshirt).

Fabric Color: For screen printing on darker color fabrics, a white layer before your print is necessary and may cost a little bit more.

Number of Colors: The more colors your print requires the higher the cost is for screen printing, however, if you have a large quantity, this cost may be a lot lower as you can have access to deeper discounts.

Quantity: With screen printing, the number of pieces will dictate the majority of your cost. This is the most important factor that will most likely dictate the right method for you.

Author: Irene Floridia - Content Creator

Need more information? Hit us up! and we will be glad to walk you through the process.

Are you ready to make a choice and place an order? Click Here!